1. Reduces Total Ammonia to <1 mg/L

year-round, even in <0.5°C water

2. Polishes cBOD to <5 mg/L, TSS to

<10mg/L, and provides partial

effluent disinfection

3. O&M requirements similar to an

aerated lagoon

1. Nitrification in any climate

2. Post-lagoon polishing

3. Airport de-icing fluid treatment

4. Decentralized wastewater

treatment

5. Water reuse applications

1. Colesburg, Iowa

2. Glencoe, Ontario

3. Harrah, Washington

4. Long Plain First Nation, Manitoba

5. Mentone, Indiana

6. Misipawistik Cree Nation, Manitoba

7. Buffalo-Niagara International

Airport, New York

8. Calgary International Airport,

Alberta

9. Food Processing Plant, Wisconsin

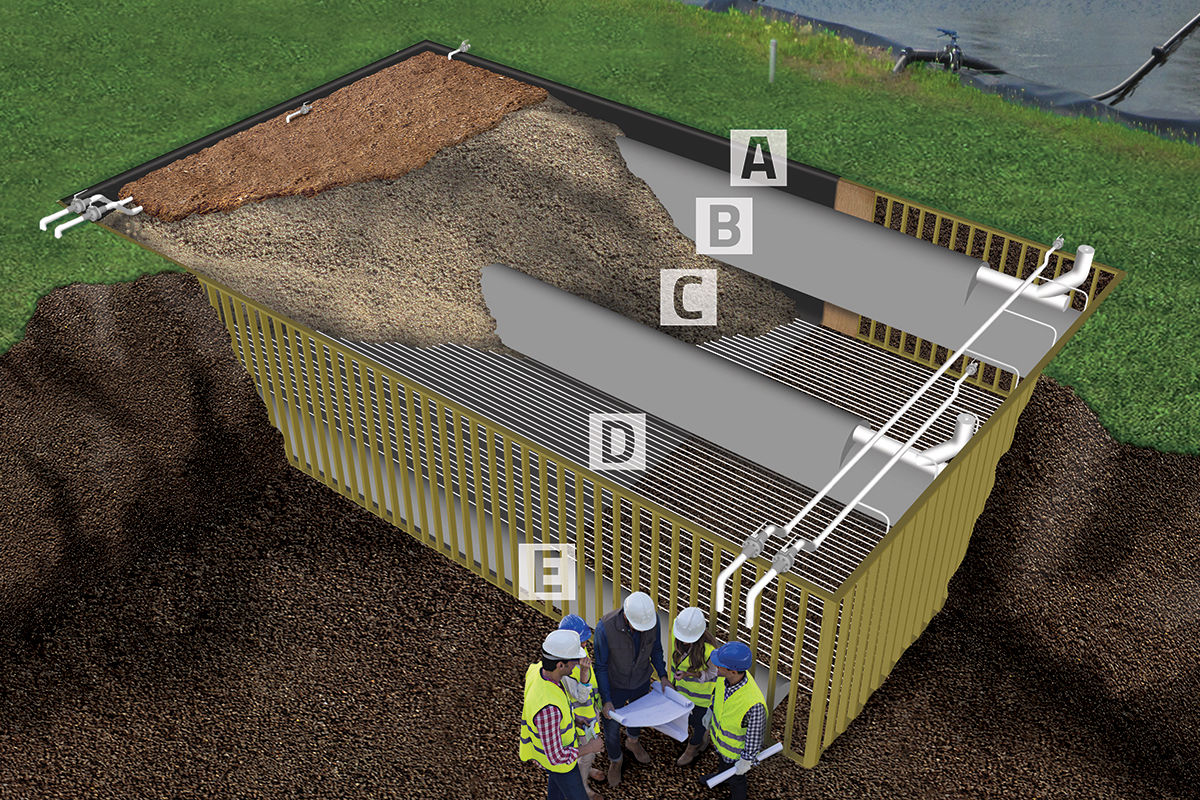

Using the patented Step-Feed process, the SAGR overcomes each of the four factors that would otherwise prevent nitrification:

1. Oxygen: The stone bed is fully aerated, meaning

there is plenty of dissolved oxygen for the

nitrifying bacteria even in the dead of winter.

2. Surface area: The clean stone is sized to

optimize hydraulic conductivity as well provide

ample surface area for the nitrifying bacteria to

grow on.

3. Competition from cBOD: SAGR beds are sized to provide cBOD polishing in addition to nitrification.

4. Cold water temperatures: Because nitrifying bacteria grows much more slowly in cold water, the SAGR process prebuilds and stores nitrifying bacteria while the water is warm so that it is already in place once metabolism and reproduction slow in cold water.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.