1. Easy upgrade for activated

sludge-based treatment plants2.

Handles variable loading

2. Handles high strength and/or

highly-variable loading

3. Reduces clarifier loading

4. Media size optimized for large

surface area while allowing for

more coarse screening.

5. Operational simplicity

6. Minimizes footprint

1. Nitrification for Total Ammonia-

Nitrogen compliance

2. Denitrification for Total

Nitrogen/nitrate compliance

3. BOD reduction

4. Enhanced biological phosphorus

removal (EBPR)

5. Activated sludge plant upgrades

6. New IFAS installations

OUR TECHNOLOGY

NEI is the exclusive source for BioPorts™ Integrated Fixed-film Activated Sludge (IFAS). BioPorts combines concentrated attached-growth kinetics with unmatched biological treatment expertise to create an intensified nitrification, denitrification, BOD removal, and even biological phosphorus removal technology.

Why do you need a BioPorts system? BioPorts technology installed at your plant allows you to:

- Customized, intensified biological nutrient removal (BNR) allows you to meet any or all of your BOD, ammonia, nitrogen, or phosphorus requirements.

- Compact design allows your plant to do more within the basin you already have

- Combination of superior components and process design expertise ensures your IFAS system is designed for your specific application and will work as intended.

How it works

RETAINING AND OXYGENATING BIOMASS TO INTENSIFY TREATMENT TODAY AND BE READY FOR TOMORROW.

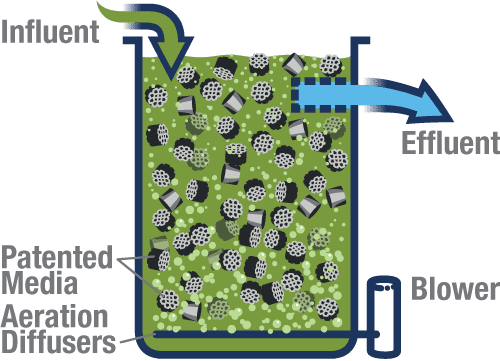

Understanding the basics of how BioPorts™ IFAS works involves some of the same fundamentals underpinning the related moving bed biofilm reactor (MBBR) process.

Biomass is easiest to retain when it’s fixed to a surface. Whether the intent is to remove BOD, nitrify ammonia, or even denitrify nitrates, growing biomass on a surface minimizes the washout that occurs in a suspended-growth environment. BioPorts provides that surface area—and plenty of it—in the form of dynamic media that is submerged and contained in a tank.

While the biofilm is fixed on the media, the media itself circulates in the tank. The integrated aeration in the tank not only ensures high dissolved-oxygen levels throughout, it also moves the media within the tank, enabling a more even distribution of loading and oxygenation to the biomass.

As a result, BioPorts™ IFAS can accommodate rapid increases in loading or flows. Because there is ample surface area for biomass expansion and basin mixing effectively distributes the biofilm-laden media, loading and oxygen throughout, BioPorts IFAS installations are able to address high strength or highly-variable loading more effectively than traditional activated sludge basins.

A BioPorts IFAS system also reduces loading to your clarifiers. Because the BioPorts media retain more of the treatment biomass in the basin, your IFAS system can treat substantially more BOD or nutrients, while contributing less mixed liquor suspended solids (MLSS) loading to clarifiers.

| US | Metric | |

|---|---|---|

| Outer diameter | 0.70 in | 18 mm |

| Cylinder length | 0.55 in | 14 mm |

| Biologically-active surface area | 179 ft²/ft³ | 589 m²/m³ |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Specific gravity | 0.96 in | |

| Max aerobic fill capacity | 67% | |

| Max anoxic/anaerobic fill capacity | 50% |

| US | Metric | |

|---|---|---|

| Outer diameter | 0.68-0.78 in | 17-20 mm |

| Cylinder length | 0.35 in | 9 mm |

| Biologically-active surface area | 287 ft²/ft³ | 942 m²/m³ |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Specific gravity | 0.96 in | |

| Max aerobic fill capacity | 67% | |

| Max anoxic/anaerobic fill capacity | 50% |

There are many factors which can influence the cost of a BioPorts system, including design flows, loading, treatment requirements, and existing infrastructure. The best way to determine the cost for your specific application is to submit your RFP to our project development team.

Based on its small footprint design and modular scalability, BioPorts is among the most simple wastewater treatment solutions to upgrade, whether your focus is further nitrification or BOD removal, denitrification to meet Total Nitrogen limits, or beyond.

Almost never. The media is sized so that it can be retained by coarse effluent screens for no downstream media loss, and it is built from durable HDPE that means the BioPorts media that you start with should last the life of your installation.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.