1. Cloth disks remove particles <10μm with no fouling

2. No downtime for routine inspections or maintenance to individual disks

reduces redundancy requirements

3. Can reduce TP to <0.1 mg/L as infini-D Zero-Downtime Phosphorus Removal solution.

1. Phosphorus removal

2. Tertiary filtration

3. Post-lagoon TSS filtration

4. Effluent reuse/recycle

5. Membrane pretreatment

6. Precipitate removal

1. Camp Verde, Arizona (water reuse)

2. Sundridge, Ontario (phosphorus

removal)

THE NEI SOLUTION:

INFINI-D™

The centrepiece of the NEI solution is the infini-D™ Zero-Downtime Cloth Disk Filter, a revolutionary improvement on the tried-and-true pile cloth disk filter.

Why a disk filter? Disk filters have a small footprint and can be installed into purpose-built or existing steel or concrete tanks.

Why a pile cloth disk filter? Pile cloth disk filters offer high effluent quality from easy-to-maintain disks. No fixed pore-sizes means the risk of fouling is reduced, and the cloth enables an outside-in flow that permits low-backwash vacuum-based cleaning.

Why the infini-D™ Zero-Downtime Cloth Disk Filter? Our infini-D system includes a patented individual effluent port on each disk, enabling disk effluent to be isolated and each disk to be separately inspected, maintained and/or replaced, all without dewatering and while the rest of the disks remain in operation and the entire system remaining online. This built-in redundancy minimizes downtime and the need for backup filtration systems.

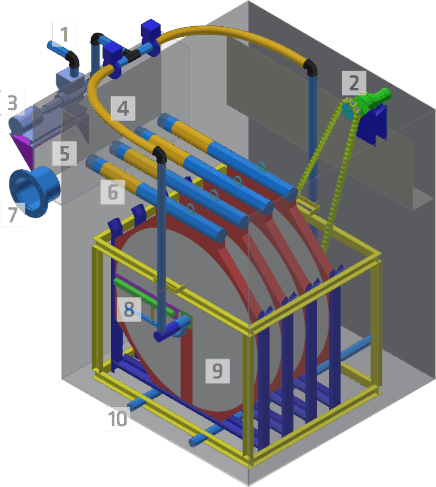

LEGEND:

1. Reject waste

2. Drive motor

3. Vacuum pump

4. Vacuum line

5. Discharge trough

6. Discharge port

7. Effluent

8. Vacuum head

9. Filter disk

10. Sludge withdrawal

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.