Where the Bow and Elbow Rivers meet in the south of Alberta, lies the City of Calgary. It is in an area of both foothills and prairies, located approximately 80 km (50 miles) east of the Canadian Rockies.

In 2016, Calgary was one of only three cities in Canada that saw their population grow by more than 100,000 people over a 5-year period. With a current population of over 1.2 million, Calgary’s economy includes energy, financial services, film and television, transportation and logistics, and technology sectors.

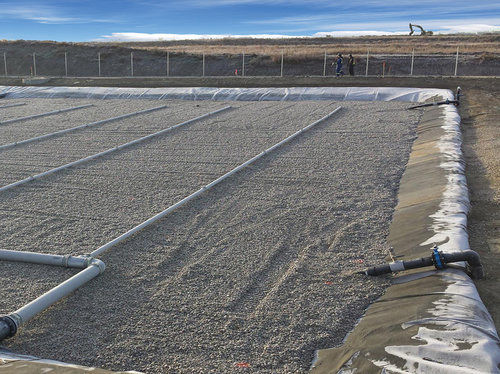

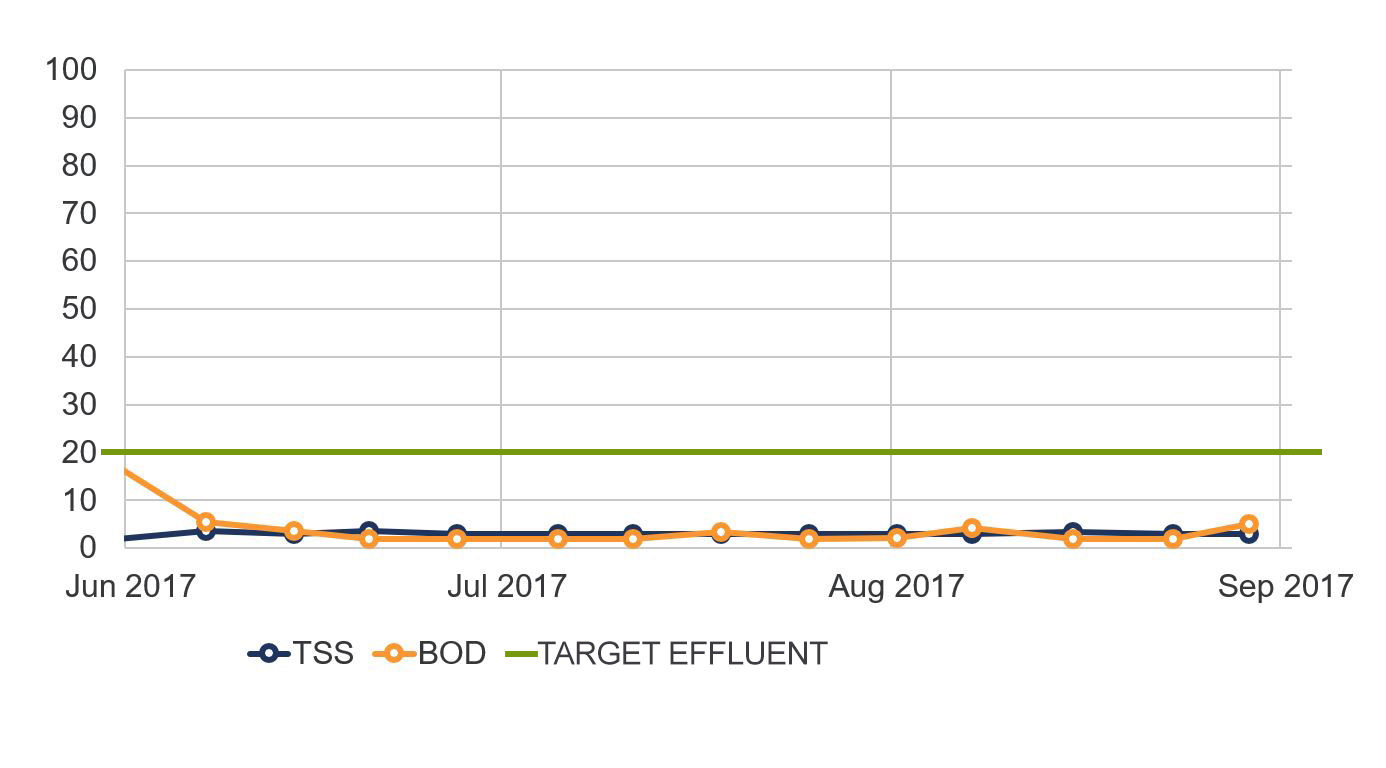

The well-placed geography of Calgary International Airport (known by airport code “YYC”) make it a natural hub. This ideal location, combined with city growth, has contributed to an increase in passenger volume by almost 15.5 million since 2015, tying with Montreal’s Pierre Elliott Trudeau as the third busiest airport in Canada. As part of this growth, the amount of storm water contaminated with aircraft deicing fluid (ADF) discharged by the facility also increased.

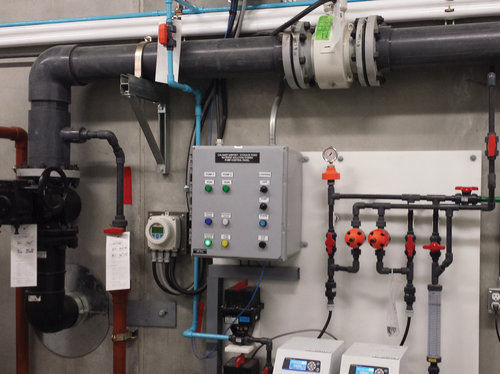

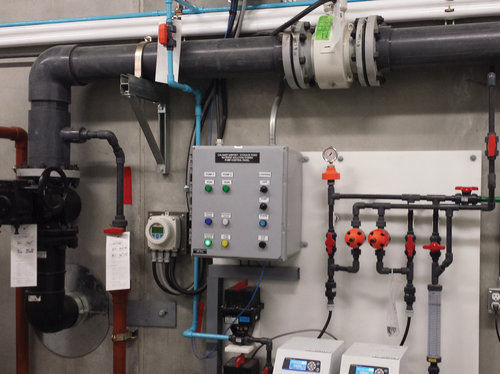

In 2015, the City of Calgary informed the airport that discharges of glycol-contaminated stormwater to the city’s sanitary sewer system were having a negative impact on the City’s ability to service new residential and industrial developments. The City strongly encouraged YYC to treat their water to stormwater discharge standards prior to discharge into the sewer system. This request, combined with the rising cost of treatment surcharges levied by the City, meant a case was developing for on-site treatment of contaminated storm water.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.