1. Hits industry-lowest

phosphorus levels

2. Lowest capital, O&M costs

3. Continuous flow; no backwash

interruptions, no changing media

4. Modular design for ease of

capacity expansion

5. No change in effluent quality

during backwash

6. Simple operation, lowest chemical

usage ratios

1. Phosphorus removal

2. Trace metals removal

3. Municipal wastewater

4. Industrial mining

5. Water reuse (Title-22/Class 1A)

1. Case Studies:

2. Burrillville, RI

3. Citronelle, AL

4. Marlborough, MA

5. Military Base, MD

Why do you need a Blue PRO® system? Blue PRO® technology installed at your plant allows you to:

1. Meet 20 µg/L (0.02 mg/L) Total Phosphorus limits

2. Meet µg/L-ng/L metals limits

3. Reduce plant chemical usage

4. Eliminate high-rate media backwashes

5. Eliminate replacement/loss of media

Blue PRO® reactive filtration can be installed into concrete tanks or purpose-built fiberglass or stainless tanks.

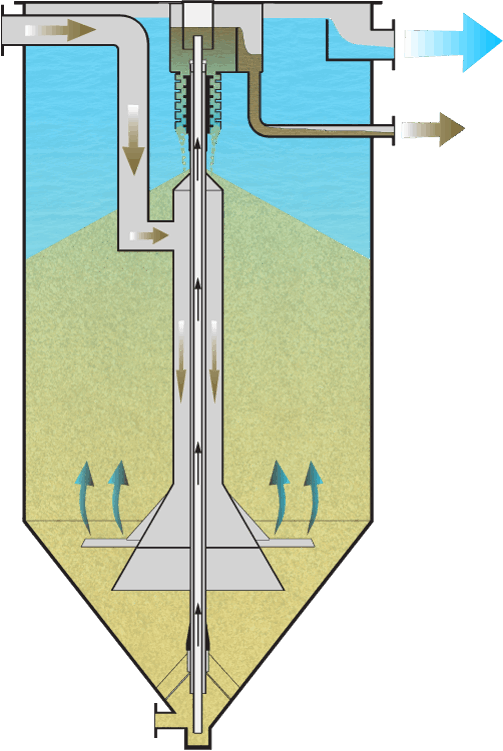

The Blue PRO filter is built on Nexom's own Centra-flo® continuous-backwash sand filter process (pictured at right). In this process, influent is distributed across almost the entire cross-sectional area of the filter near the bottom of the sand column. Water is filtered as it flows upward, and the sand coated with hydrous ferric oxide (HFO) attracts and reacts with the phosphorus and metals. Sand is moving downward by gravity to an airlift device. While the filtered water exits near the top of the filter, the airlift transports the phosphorus- or metals-laden media up into the washbox where the discharged HFO coating and adsorbed contaminates are separated from the media. Water velocities in the washbox are carefully designed to carry away the contaminates while allowing the media to fall to the filter bed. The freshly scrubbed media from the washbox is recoated with HFO as its cycle begins again.

The Blue PRO reactive filtration process overcomes a critical obstacle to achieving efficient phosphorus removal in bulk aqueous solutions by providing a very large reactive surface area within the media bed, resulting in guaranteed contact of phosphorus with HFO and its high adsorptive capacity. The adsorptive surface in Blue PRO filters is a continuously regenerated HFO coating that forms on the surface of the sand media. Coagulation followed by physical separations processes (clarifiers, filters, membranes, etc.) simply cannot compare to the efficiency of adsorptive phosphorus removal.

Waste HFO, phosphorus, and solids are removed from the filter through the backwash or reject stream. Recycling this backwash upstream provides the added benefit of phosphorus pre-treatment in primary or secondary treatment systems, further guaranteeing the achievement of the discharge phosphorus target as well as lowering the overall plant chemical ratio. The phosphorus is chemically bound, exiting the site with the plant sludge. Integration of the Blue PRO technology does not require change in the plant's sludge handling system. Blue PRO uses 30% less chemical than comparative technologies for ultra-low phosphorus, therefore producing less sludge. The waste HFO also helps with odor control and can reduce water content in biosolids.

The Blue PRO system is available in several models and configurations. The modular nature of the filters allows for ease of engineering system expansion. The filters are available as freestanding fiberglass or stainless steel units or can be integrated in multi-module concrete cells. Control systems and smaller filters may be mounted on skid systems for mobility or ease of commissioning.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.