1. Reduce BOD by 20-40%,

TSS by 30-80%

2. Treat in 5% of the space

required by conventional

clarification

3. Use less energy than other

rotating belt filters

4. Automated self-cleaning cuts

85% of routine maintenance

1. 0.1-50 MGD plant-optimizing

primary treatment

2. Increases plant capacity by

reducing solids, nutrient, and BOD

loading to subsequent processes

3. Replaces failing clarifiers with

efficiency in a small footprint

4. Removes grease, oils, and fats

using patented WaterKnife process

1. Wilmington, VT

2. Valparaiso, IN

3. Pocahontas, WV

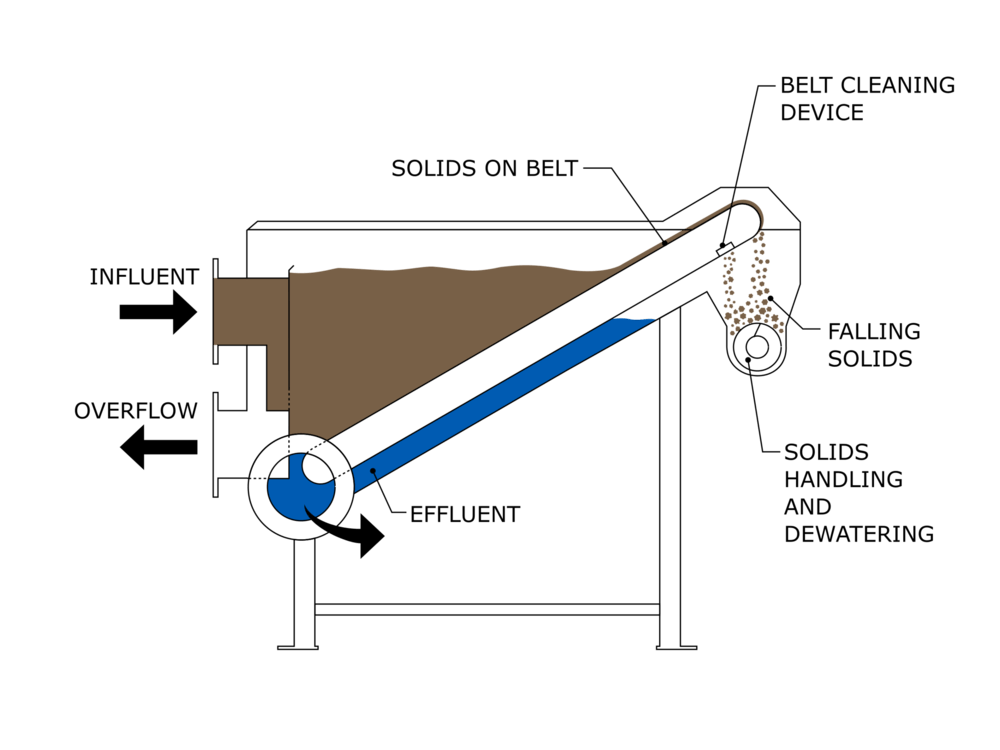

LOOK INSIDE THE ECOBELT

EcoBELT™ removes solids using a continuous-loop fine mesh belt screen. As the screen moves it acts as a conveyor and carries solids out of the incoming wastewater. The patent-pending cleaning system discharges the solids from the belt screen and deposits them into the screenings hopper. Periodic hot-water flushes further clean the belt screen by removing oil and grease that may accumulate over time. An optional screw press dewaters the collected screenings to between 20-40% dry solids while screened wastewater continuously passes through the unit.

How long does a belt last?

Belts used in the EcoBELT are specially-designed to last twice as long as many of its competing belts. While impacted by factors including types of pretreatment in the plant configuration and belt loading, belts last 2 years on average. And though belt replacement is infrequently required, the EcoBELT is designed to make it a smooth exercise for plant operators. Our team trains operators to swap out the EcoBELT belt in 30 minutes (other RBFs take 6-8 hours). Don’t risk having another RBF’s belt fail during peak flows; with EcoBELT you’ll be back online 16x faster!

The EcoBELT™ successfully reduces TSS and cBOD5, but its purpose is greater; it exists to improve the function of the entire plant in a small footprint with a whole-lifecycle cost that is a fraction of what conventional clarification could cost.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.