1. Wastewater treatment

intensification offers more

treatment capacity in a small

footprint

2. Handles variable loading

3. Media size optimized for huge

surface area while allowing for

more coarse screening

4. Operational simplicity

1. Nitrification

2. Pre- or post-denitrification

3. BOD reduction

4. Activated sludge plant upgrades

(as part of BioPorts iFAS)

5. New IFAS installations (Integrated

Fixed-film Activated Sludge)

6. Small-footprint lagoon pre-

treatment or polishing

1. Leeds, AL municipal treatment

intensification

2. Horse Cave, KY industrial BOD

roughing

3. Seneca Landfill, PA landfill

leachate treatment

4. Oak Creek, CO municipal

wastewater

5. Cheyenne, WY oil & gas refinery

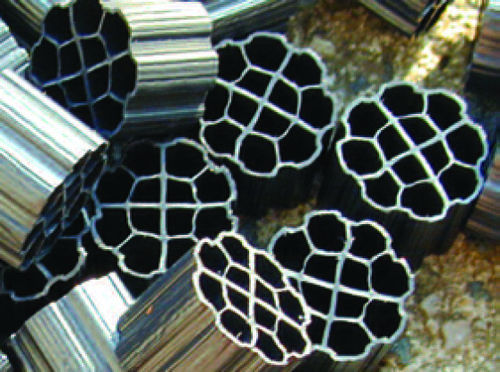

OUR TECHNOLOGY: BIOPORTS MBBR

BioPorts™ MBBR

NEI is the exclusive source for the BioPorts™ moving bed biofilm reactor (MBBR). BioPorts combines concentrated attached-growth reaction kinetics with NEI's unmatched biological treatment expertise to create an industry leading nitrification, denitrification, and BOD removal technology.

Why do you need a BioPorts system?

BioPorts technology installed at your plant allows you to:

- Meet ammonia, BOD, total nitrogen and/or nitrate

limits

- Compact design allows your plant to do more with

the space you already have

- Coarse screens and Screen Scour™ makes

BioPorts™ a low-maintenance, simple-to-operate

solution

BioPorts MBBR media can be used in purpose-built tanks or to turn activated sludge basins into IFAS systems.

How it works

RELIABLE, SIMPLE, INTENSE.

BioPorts MBBRs work based on a series of basic principles, offering them three key advantages:

BioPorts MBBRs are reliable.

When flows increase quickly, it can overwhelm an activated sludge system’s capacity and cause biological washout.

With BioPorts, your biology is fixed where you need it: in your treatment basin, fixed to the surface of BioPorts media which themselves are retained using coarse screens. No more biology washout.

BioPorts MBBRs are simple.

Balancing return activated sludge is a challenging part of managing an activated sludge plant, and although the improvements in oxygen transfer make it well worth it, managing membrane-based or, more challenging yet, fixed-pore fine-bubble aeration adds to an operator’s workload.

With BioPorts MBBR, you don’t need to return your activated sludge because, again, your active biology is fixed directly to the media retained in the basin using coarse screens. And because moving media both impedes the rise and breaks up the aeration bubbles, lower-maintenance membrane-free diffusers can be used while achieving the same oxygen transfer.

BioPorts MBBRs are intense.

When your facility was first designed, it probably wasn’t being asked to handle the high strength or variability as you’re seeing now, and that was when it was brand new!

Create and retain the density of treatment to better handle today (and tomorrows’s) loading levels and their fluctuations, all thanks to your BioPorts MBBR.

| US | Metric | |

|---|---|---|

| Outer diameter | 0.70 in | 18 mm |

| Cylinder length | 0.55 in | 14 mm |

| Biologically-active surface area | 179 ft²/ft³ | 589 m²/m³ |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Specific gravity | 0.96 in | |

| Max aerobic fill capacity | 67% | |

| Max anoxic/anaerobic fill capacity | 50% |

| US | Metric | |

|---|---|---|

| Outer diameter | 0.68-0.78 in | 17-20 mm |

| Cylinder length | 0.35 in | 9 mm |

| Biologically-active surface area | 287 ft²/ft³ | 942 m²/m³ |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Specific gravity | 0.96 in | |

| Max aerobic fill capacity | 67% | |

| Max anoxic/anaerobic fill capacity | 50% |

There are many factors which can influence the cost of a BioPorts system, including design flows, loading, treatment requirements, and existing infrastructure. The best way to determine the cost for your specific application is to submit your RFP to our project development team.

Based on its small footprint design and modular scalability, BioPorts is among the most simple wastewater treatment solutions to upgrade, whether your focus is further nitrification or BOD removal, denitrification to meet Total Nitrogen limits, or beyond.

Almost never. The media is sized so that it can be retained by coarse effluent screens for no downstream media loss, and it is built from durable HDPE that means the BioPorts media that you start with should last the life of your installation.

If you are looking to achieve <1 mg/L of ammonia in freezing cold water, NEI has already solved that problem with the SAGR, which has numerous proprietary advances that help it overcome limitations related to cold lagoon effluent.

BioPorts is tremendously effective in many post-lagoon settings, so to identify which solution is best for you, reach out and let our NEI process engineers guide you.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.