The goal at Misipawistik Cree Nation was to create a process that was cost effective and simple to operate, while also providing consistent performance in winter water temperatures (November through April) that can fall below 1°C.

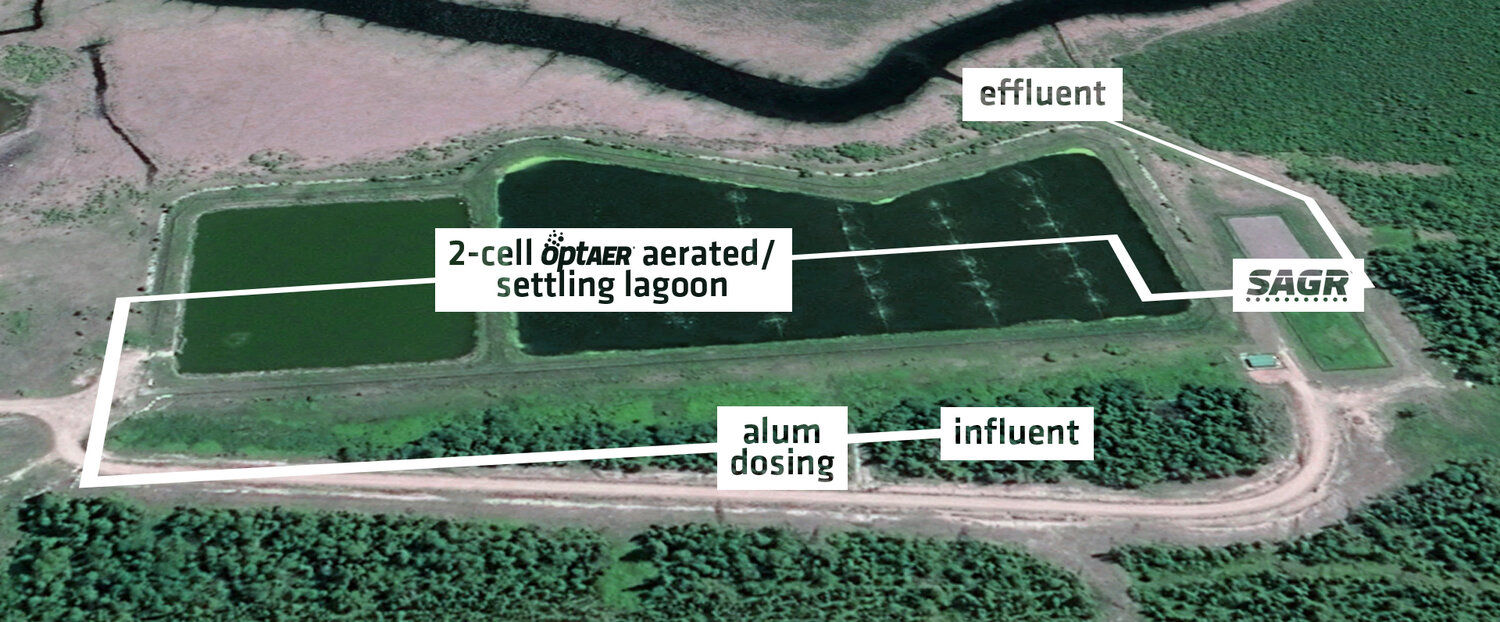

Biological wastewater treatment using lagoons has been a common answer for communities seeking low operations and maintenance (O&M) solutions. But they come with significant challenges for cold climates. In a typical unaerated lagoon, once ice forms on the surface, the ability of oxygen from the air to dissolve into the water and reach the nitrifying (ammonia-removing) bacteria disappears. Even when lagoons are aerated, near-zero water temperatures slow bacterial metabolism down to a fraction of summer rates. Working with MCN, we utilized the existing facultative lagoons for primary treatment, upgraded with an optAER aeration system for enhanced BOD and TSS removal. Aeration provides oxygen, residence and contact time for the natural bacteria, which ultimately convert the wastewater contaminates (BOD, ammonia, and TSS) to carbon dioxide, water, inert ash and nitrates. It also provides effective odor control.

The optAER aeration system at MCN consisted of floating laterals and a pair of positive displacement blowers. With floating laterals, lagoon cells don’t need to be dewatered or taken out of service for installation or maintenance - all maintenance work can be completed from a boat, using a 2-person crew. In comparison to conventional mechanical treatment facilities, optAER-enhanced lagoons maintain the simplicity of a lagoon system for a fraction of the costs to construct and operate.

The two blowers provide the necessary air supply during normal system operations, in a duty/standby configuration. The benefits of using positive displacement blowers include consistent flow of air to the lagoon regardless of discharge pressure, as well as simple operation and maintenance. Each blower included a sound-reducing enclosure.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.