We, in collaboration with Urban Engineers, and Stantec designed a novel robust on-site treatment system that proved very cost effective in initial capital and O&M. The system can handle the high flush flow, low propylene glycol concentration of spring. During winter operations, the system is capable of handling the low flow high polypropylene concentration.

As an added advantage, the system was integrated with the stormwater management system to produce an effluent quality surpassing regulatory requirements on a year round basis.

The system comprises of vertical flow aerated gravel bed, a variation of SAGR®. Underground storage tanks are used to store and equalize flow prior to feeding the SAGR® process. Grit removal chambers between the equalization tanks and the SAGR® process remove particulate matter that could otherwise adversely affect process pumps and SAGR® hydraulics.

The gravel bed provides required surface area for BOD reducing heterotrophic bacteria to attach and grow. Air introduced through FBA® LINEAR aeration system provides a minimum of 2 mg/L disolved oxygen throughout the bed. The design and operation of the system is loading dependent as opposed to hydraulically limited. As a result, the process can handle a high flow at low BOD concentration (up to 1.2 MGD), a condition typically seen during spring thaw and summer operation, or the process can treat high influent BOD5 (>1000 mg/L) at low throughput to an effluent quality of 30 mg/L BOD5.

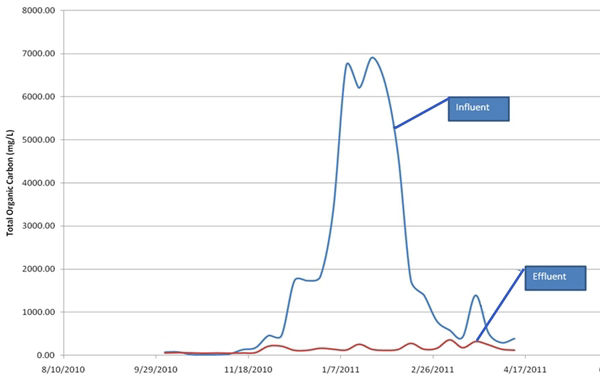

The bed is sized to ensure a balance between biomass accumulation and degradation. As a result, chances of long term fouling that would result in diminished hydraulic conductivity are minimized. Performance data of the vertical flow SAGR is as seen in the chart.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.