Seneca Landfill is located about 25 miles north of Pittsburgh, where it discharges wastewater continuously into Connoquenessing Creek. Water from the Connoquenessing flows southwest through the Lake Oneida reservoir before ultimately terminating at the Beaver River.

Following a study by the U.S. Public Interest Research Group in 2000, where Connoquenessing Creek was named one of the most polluted waterways in the US, sites that discharge into the creek became subject to stricter ammonia permits on all wastewater being released.

Ammonia management is an increasing concern within the wastewater industry. Research suggests effluent un-ionized ammonia must be as low as 0.2 mg/L to ensure non-toxicity.

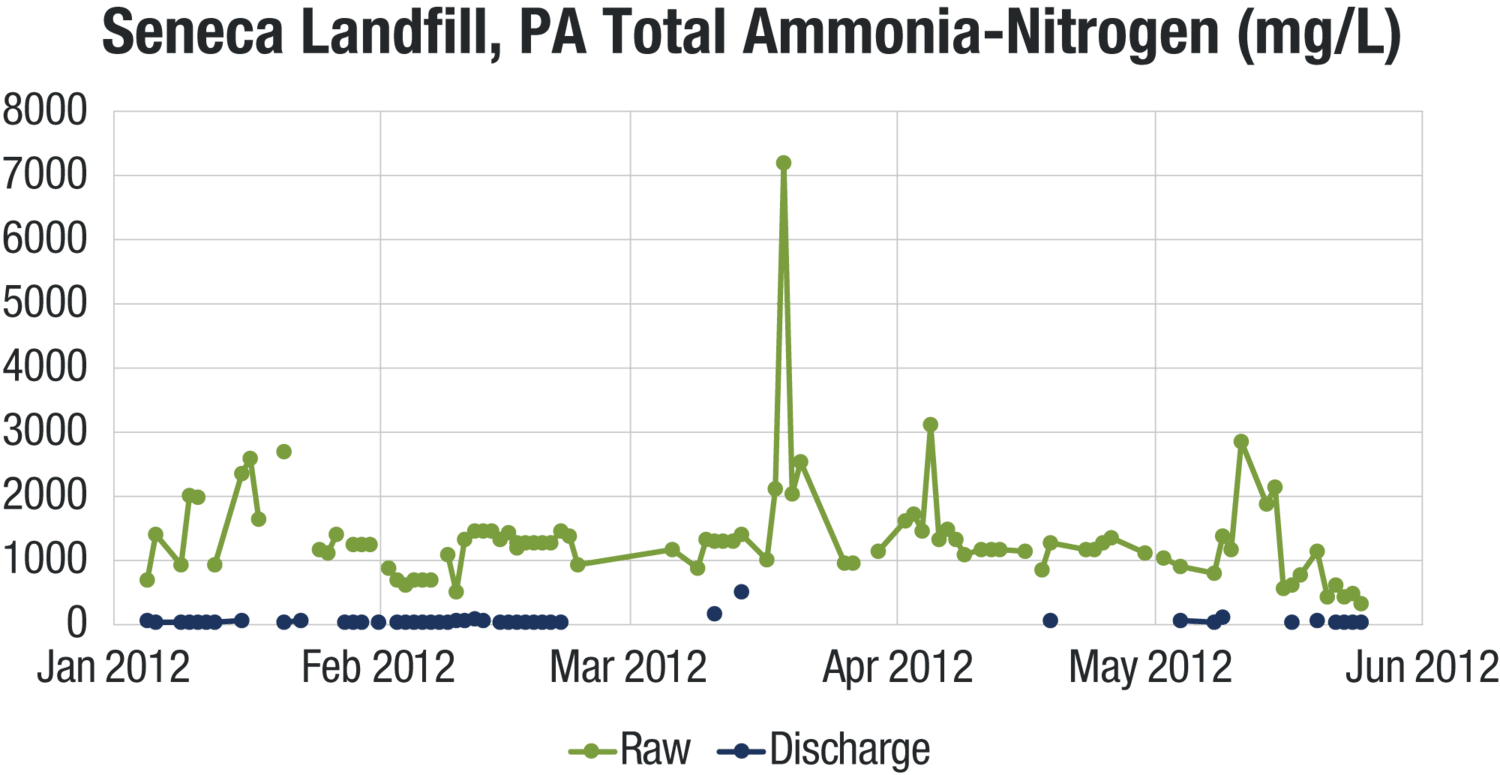

However, not only is un-ionized ammonia toxic to aquatic life - it can promote excessive algae growth and the loss of dissolved oxygen. Landfill leachate is a common waste type characterized by extremely high BOD and ammonia spikes. While the average ammonia level in the influent is 1,400 mg/L, Seneca Landfill has historically reported days where the influent ammonia have been higher than 3,000 mg/L. In keeping with their permit limit, Seneca Landfill needed to obtain an onsite ammonia effluent limit of less than 4.7 mg/L and was not consistently able to meet that target using their own system, thereby forcing them to incur additional costs for off-site treatment.

Part of the cause of these high ammonia levels was the decision of the landfill owners to extract the methane gas being produced by the landfill. When organic matter ends up in a landfill, it breaks down over time. As it breaks down, it generates gases, including methane. Methane is a greenhouse gas capable of contributing to global warming and needs to be diverted from entering the atmosphere. Traditionally, landfills use flares to burn off both excess methane and CO2. Instead, Seneca Landfill wished to capture the methane and convert it into a clean form of natural gas for future use – including helping to power the landfill itself. However, the methane extraction process produces condensate, a wastewater with an even higher concentration of ammonia than the original landfill leachate, rendering the existing wastewater treatment system insufficient.

The original system at Seneca Landfill consisted of three bio-towers, filled with outdated trickling filter media. At the time, only two were in operation - all of which contributed to the system being unable to reduce effluent ammonia to required levels. In consultation with engineers at Bassett Engineering and the operators at Seneca Landfill, a decision was made to convert the existing bio-towers to aerobic BioPorts™ MBBR reactors, which would eventually run in series. The bio-towers would be updated one at a time with new BioPorts™ media, which also provided an opportunity to measure effluent characteristics at three different intermediate flow configurations along the way, in addition to the final reactor configuration.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.