Key Details

Technology: BioPorts™ iFAS

(Integrated Fixed-Film Activated Sludge)

ADVANTAGES

- Easy upgrade for activated sludge-based treatment plants2. Handles variable loading

- Handles high strength and/or highly-variable loading

- Reduces clarifier loading

- Media size optimized for large surface area while allowing for more coarse screening.

- Minimizes footprint

APPLICATIONS

- Nitrification for Total Ammonia-Nitrogen compliance

- Denitrification for Total Nitrogen/nitrate compliance

- BOD reduction

- Enhanced biological phosphorus removal (EBPR)

- Activated sludge plant upgrades

- New IFAS installations

Your Challenge: Upgrade your activated sludge plant to intensify treatment

Meet ammonia, BOD, nitrate, or even phosphorus limits: You need your activated sludge-based wastewater treatment plant to consistently hit required total ammonia-nitrogen, cBOD₅, total nitrogen/nitrate, and phosphorus removal levels.

Increase the surface area available to attached-growth biomass: By growing treatment microorganisms as a fixed film on a surface, BioPorts minimizes the washout associated with suspended-growth biomass.

Keep footprint to a minimum: Real estate is at a premium, and a lack of aeration energy or oxygen isn’t always the limiting factor.

OUR TECHNOLOGY

NEI is the exclusive source for BioPorts™ Integrated Fixed-film Activated Sludge (IFAS). BioPorts combines concentrated attached-growth kinetics with unmatched biological treatment expertise to create an intensified nitrification, denitrification, BOD removal, and even biological phosphorus removal technology.

Why do you need a BioPorts system? BioPorts technology installed at your plant allows you to:

– Customized, intensified biological nutrient removal (BNR) allows you to meet any or all of your BOD, ammonia, nitrogen, or phosphorus requirements.

– Compact design allows your plant to do more within the basin you already have

– Combination of superior components and process design expertise ensures your IFAS system is designed for your specific application and will work as intended.

HOW IT WORKS

RETAINING AND OXYGENATING BIOMASS TO INTENSIFY TREATMENT TODAY AND BE READY FOR TOMORROW.

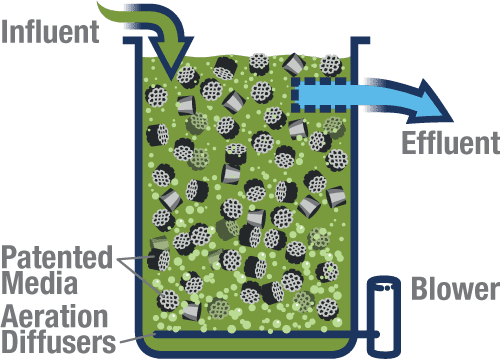

Understanding the basics of how BioPorts™ IFAS works involves some of the same fundamentals underpinning therelated moving bed biofilm reactor (MBBR) process.

Biomass is easiest to retain when it’s fixed to a surface. Whether the intent is to remove BOD, nitrify ammonia, or even denitrify nitrates, growing biomass on a surface minimizes the washout that occurs in a suspended-growth environment. BioPorts provides that surface area—and plenty of it—in the form of dynamic media that is submerged and contained in a tank.

While the biofilm is fixed on the media, the media itself circulates in the tank. The integrated aeration in the tank not only ensures high dissolved-oxygen levels throughout, it also moves the media within the tank, enabling a more even distribution of loading and oxygenation to the biomass.

As a result, BioPorts™ IFAS can accommodate rapid increases in loading or flows. Because there is ample surface area for biomass expansion and basin mixing effectively distributes the biofilm-laden media, loading and oxygen throughout, BioPorts IFAS installations are able to address high strength or highly-variable loading more effectively than traditional activated sludge basins.

A BioPorts IFAS system also reduces loading to your clarifiers. Because the BioPorts media retain more of the treatment biomass in the basin, your IFAS system can treat substantially more BOD or nutrients, while contributing less mixed liquor suspended solids (MLSS) loading to clarifiers.

BIOPORTS COMPONENTS

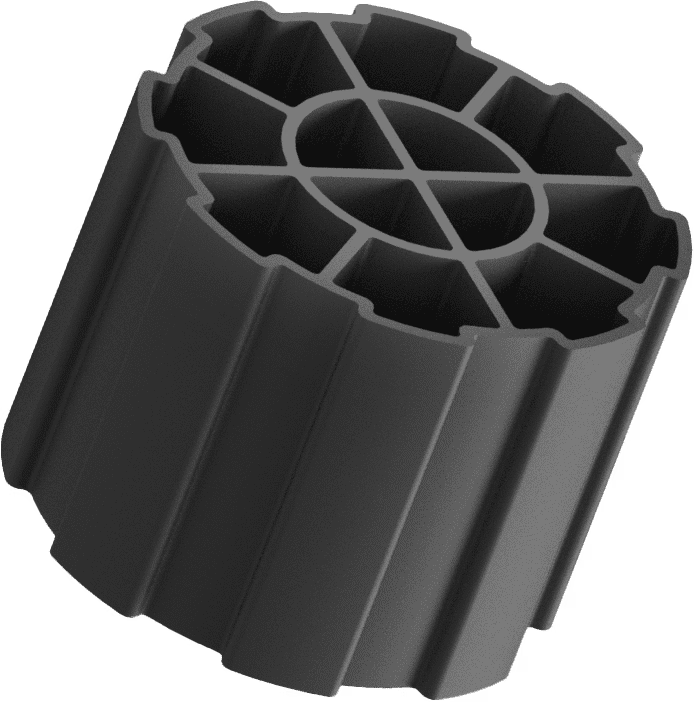

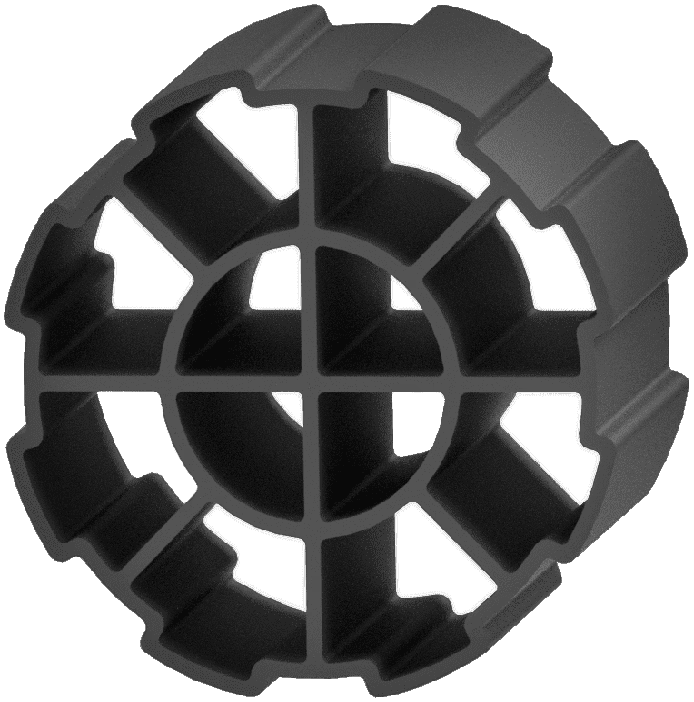

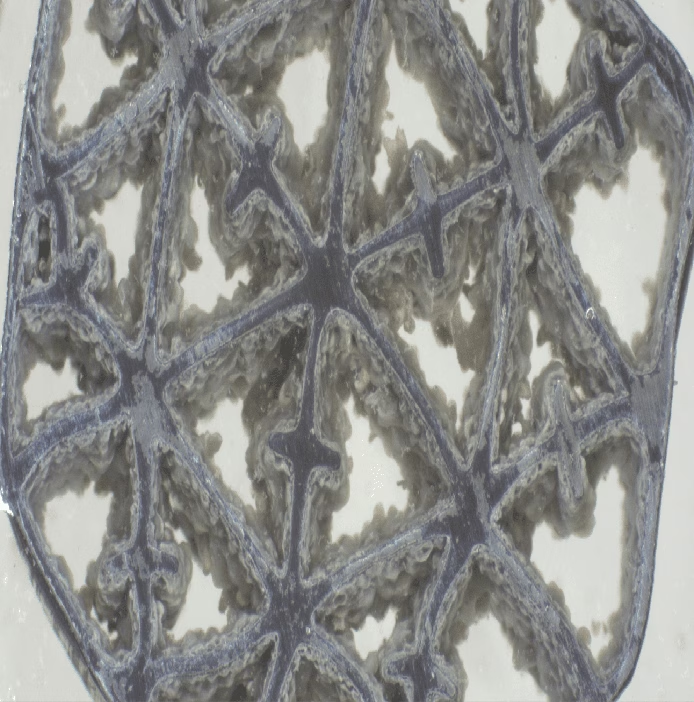

BioPorts Media: 600-14

MEDIA DESIGN

MEDIA DESIGN

MEDIA DESIGN

BIOFILM COVERAGE

Specification

| US ▾ | Metirc ▾ | |

|---|---|---|

| Specific gravity | 0.96 in | |

| Outer diameter | 0.70 in | 18 mm |

| Max anoxic/anaerobic fill capacity | 50% | |

| Max aerobic fill capacity | 67% | |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Cylinder length | 0.55 in | 14 mm |

| Biologically-active surface area | 179 ft²/ft³ | 589 m²/m³ |

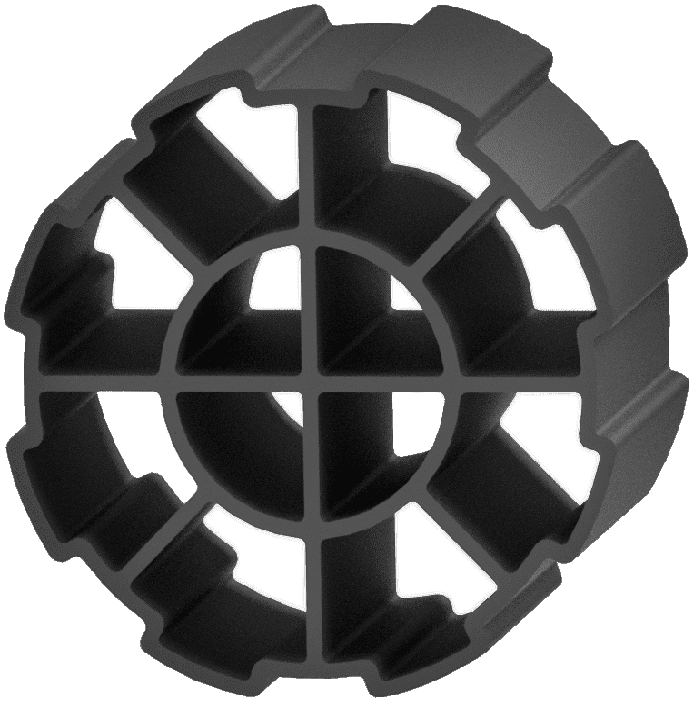

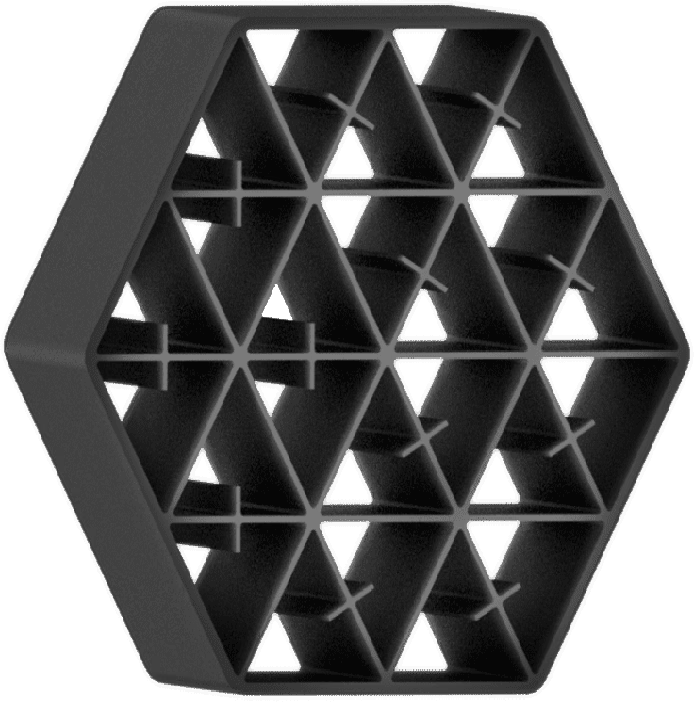

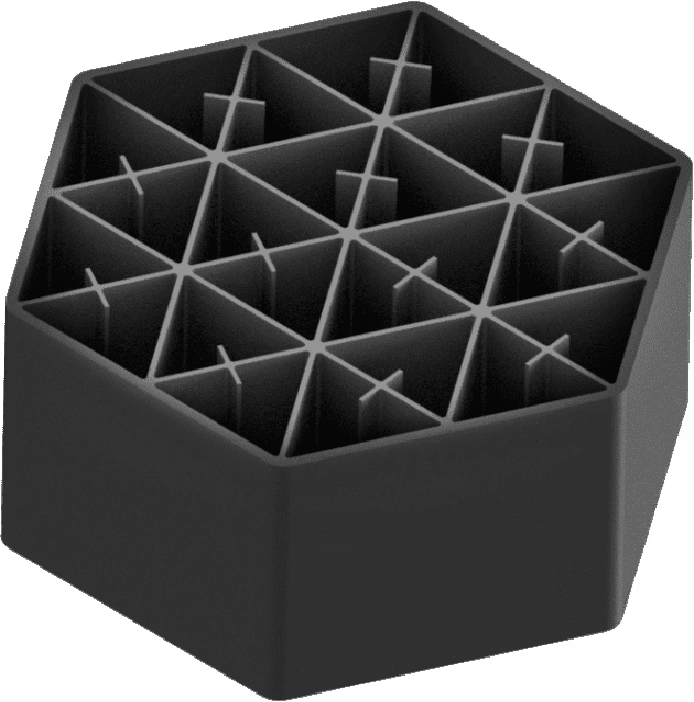

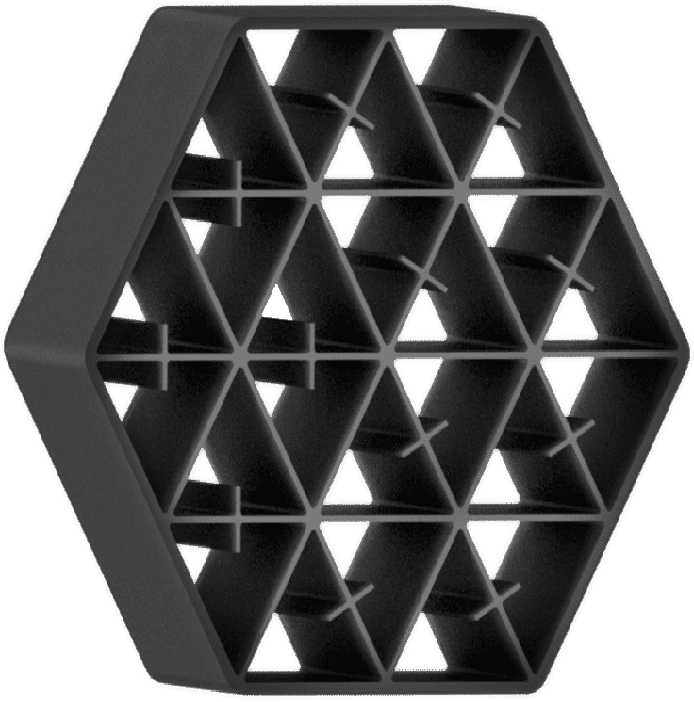

BioPorts Media: 600-14

MEDIA DESIGN

BIOFILM COVERAGE

MEDIA DESIGN

BIOFILM COVERAGE

| US ▾ | Metirc ▾ | |

|---|---|---|

| Outer diameter | 0.68-0.78 in | 17-20 mm |

| Cylinder length | 0.35 in | 9 mm |

| Biologically-active surface area | 287 ft²/ft³ | 942 m²/m³ |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Specific gravity | 0.96 in | |

| Max aerobic fill capacity | 67% | |

| Max anoxic/anaerobic fill capacity | 50% |

Media Screens

BioPorts media retention screens are fine enough to keep the biofilm-carrying media from escaping the basin, but coarse enough to allow particulates to pass through and prevent the screen from fouling or blinding.

Media screens can also be arranged in parallel to better accommodate variable flows. Vertical screens with above-surface access ports can be used to enable better access for effluent sampling or occasional screen maintenance.

Fixed Grid Aeration

Thanks to our the integration with EDI, our aeration capabilities are the envy of the industry. Most BioPorts facilities are designed with EDI fixed grid aeration within our basins to optimize performance with minimal O&M.

In fact, based on that aeration expertise, Leeds, Alabama’s BioPorts MBBR is able to achieve optimized mixing and oxygen-transfer with ~25% of the energy typically required.

WHAT IT DELIVERS

IFAS TRANSFORMS MARICOPA COUNTY, AZ TREATMENT FACILITY

The BioPorts™ process is the best choice for roughing high influent BOD, polishing ammonia, or upgrading to IFAS. In place at dozens of installations across North America, BioPorts MBBRs or IFAS installations deliver as promised and ensure that operators sleep well at night knowing they have the system in place to beat their BOD and nutrient limits.

FAQS