Key Details

Technology: BioPorts™ Moving Bed Biofilm Reactor (MBBR)

ADVANTAGES

- Wastewater treatment intensification offers more treatment capacity in a small footprint

- Handles variable loading

- Media size optimized for huge surface area while allowing for more coarse screening

- Operational simplicity

APPLICATIONS

- Nitrification

- Pre- or Post-denitrification

- BOD reduction

- Activated sludge plant upgrades (as part of BioPorts iFAS)

- New IFAS installations (Integrated Fixed-film Activated Sludge)

- Small-footprint lagoon pre-treatment or polishing

CASE STUDIES

- Leeds, AL Municipal Treatment Intensification

- Horse Cave, KY Industrial BOD Roughing

- Seneca Landfill, PA Landfill Leachate Treatment

- Oak Creek, CO Municipal Wastewater

- Cheyenne, WY Oil & Gas Refinery

Key Details

Technology: BioPorts™ Moving Bed Biofilm Reactor (MBBR)

Meet ammonia, BOD, and/or nitrate limits: You need a solution that can consistently hit required Total Ammonia-Nitrogen, cBOD₅ and Total Nitrogen/Nitrate removal levels.

Increase the surface area available to attached-growth microorganisms: By growing nitrifying and heterotrophic biomass on a surface, BioPorts minimizes the washout associated with suspended-growth systems.

Intensification maximizes treatment: In situations where your loading is high strength or highly variable, you need a system that can respond most dynamically.

OUR TECHNOLOGY: BIOPORTS MBBR

BioPorts™ MBBR

NEI is the exclusive source for the BioPorts™ moving bed biofilm reactor (MBBR). BioPorts combines concentrated attached-growth reaction kinetics with NEI’s unmatched biological treatment expertise to create an industry leading nitrification, denitrification, and BOD removal technology.

Why do you need a BioPorts system?

BioPorts technology installed at your plant allows you to:

– Meet ammonia, BOD, total nitrogen and/or nitrate

limits

– Compact design allows your plant to do more with

the space you already have

– Coarse screens and Screen Scour™ makes

BioPorts™ a low-maintenance, simple-to-operate

solution

BioPorts MBBR media can be used in purpose-built tanks or to turn activated sludge basins into IFAS systems.

HOW IT WORKS

RELIABLE, SIMPLE, INTENSE.

BioPorts MBBRs work based on a series of basic principles, offering them three key advantages:

BioPorts MBBRs are reliable.

When flows increase quickly, it can overwhelm an activated sludge system’s capacity and cause biological washout.

With BioPorts, your biology is fixed where you need it: in your treatment basin, fixed to the surface of BioPorts media which themselves are retained using coarse screens. No more biology washout.

BioPorts MBBRs are simple.

Balancing return activated sludge is a challenging part of managing an activated sludge plant, and although the improvements in oxygen transfer make it well worth it, managing membrane-based or, more challenging yet, fixed-pore fine-bubble aeration adds to an operator’s workload.

With BioPorts MBBR, you don’t need to return your activated sludge because, again, your active biology is fixed directly to the media retained in the basin using coarse screens. And because moving media both impedes the rise and breaks up the aeration bubbles, lower-maintenance membrane-free diffusers can be used while achieving the same oxygen transfer.

BioPorts MBBRs are intense.

When your facility was first designed, it probably wasn’t being asked to handle the high strength or variability as you’re seeing now, and that was when it was brand new!

Create and retain the density of treatment to better handle today (and tomorrows’s) loading levels and their fluctuations, all thanks to your BioPorts MBBR.

BIOPORTS COMPONENTS

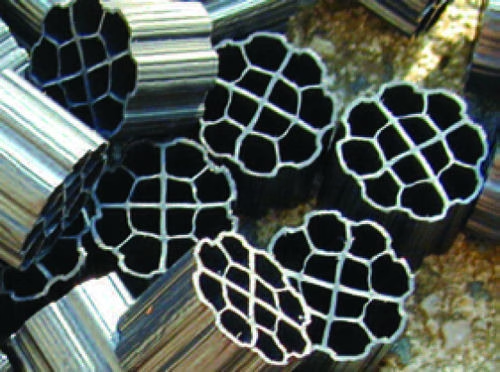

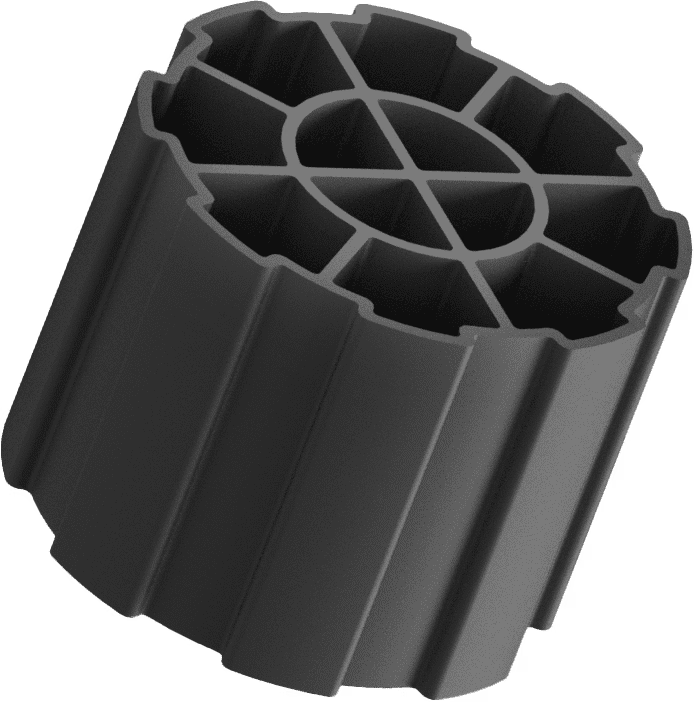

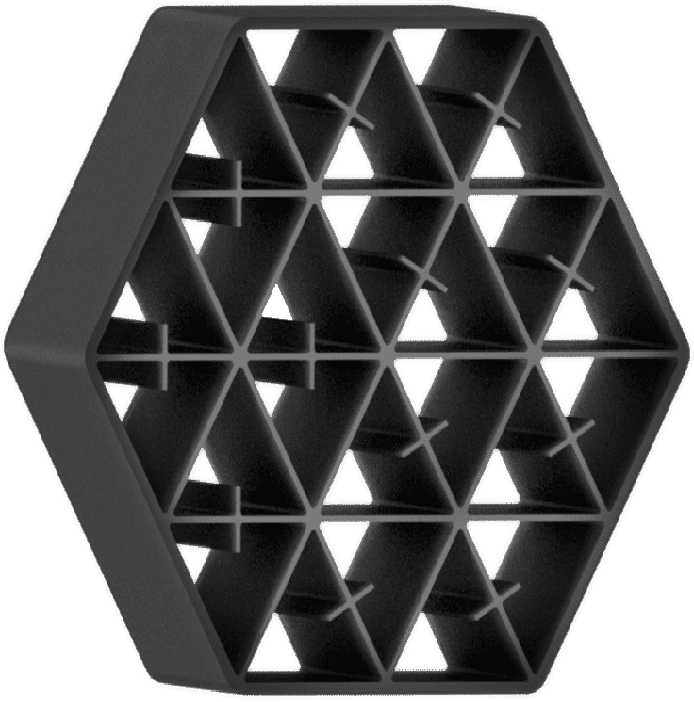

BioPorts Media: 600-14

MEDIA DESIGN

MEDIA DESIGN

MEDIA DESIGN

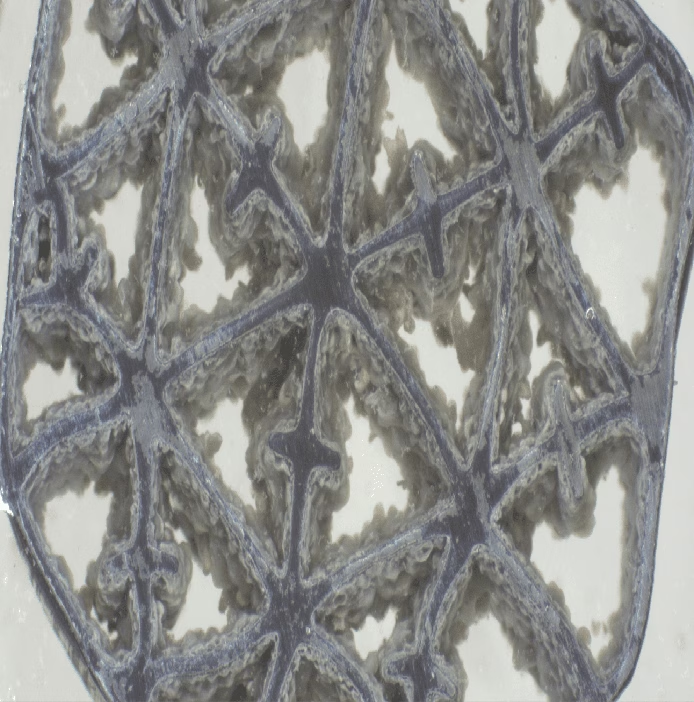

BIOFILM COVERAGE

Specification

| US ▾ | Metirc ▾ | |

|---|---|---|

| Specific gravity | 0.96 in | |

| Outer diameter | 0.70 in | 18 mm |

| Max anoxic/anaerobic fill capacity | 50% | |

| Max aerobic fill capacity | 67% | |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Cylinder length | 0.55 in | 14 mm |

| Biologically-active surface area | 179 ft²/ft³ | 589 m²/m³ |

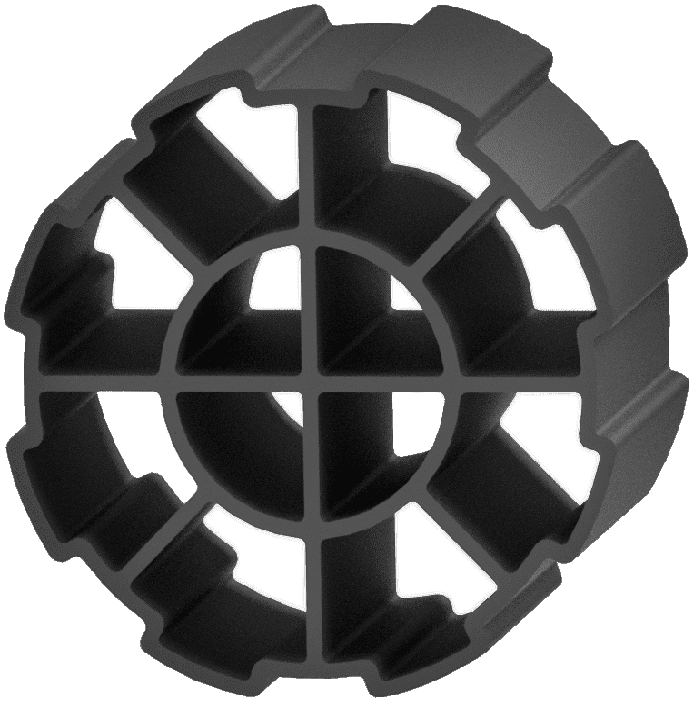

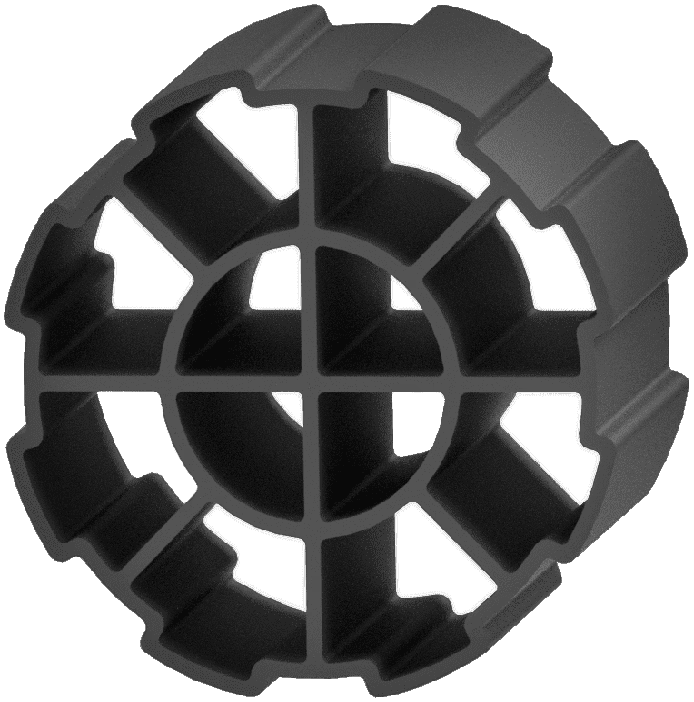

BioPorts Media: 600-14

MEDIA DESIGN

BIOFILM COVERAGE

MEDIA DESIGN

BIOFILM COVERAGE

| US ▾ | Metirc ▾ | |

|---|---|---|

| Outer diameter | 0.68-0.78 in | 17-20 mm |

| Cylinder length | 0.35 in | 9 mm |

| Biologically-active surface area | 287 ft²/ft³ | 942 m²/m³ |

| Material | High-density polyethylene (HDPE) with carbon black added for UV protection | |

| Specific gravity | 0.96 in | |

| Max aerobic fill capacity | 67% | |

| Max anoxic/anaerobic fill capacity | 50% |

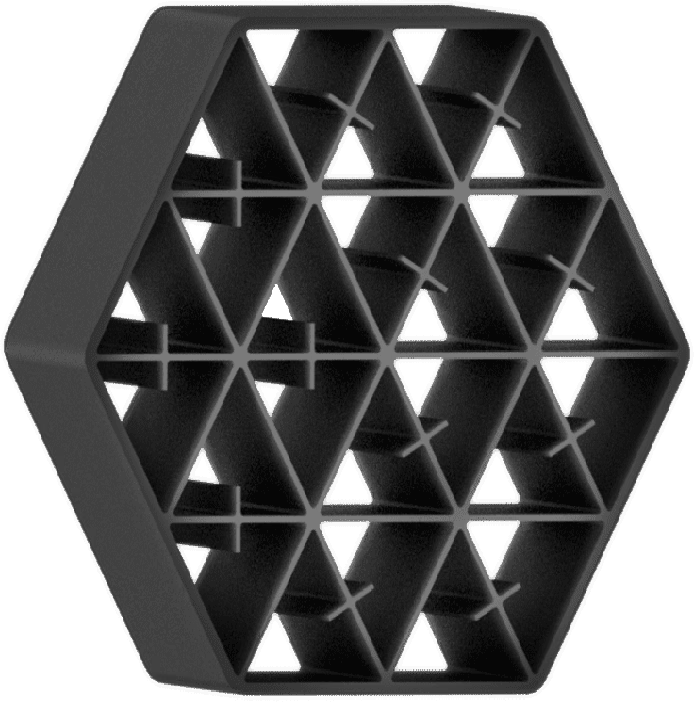

Media Screens

BioPorts media retention screens are fine enough to keep the biofilm-carrying media from escaping the basin, but coarse enough to allow particulates to pass through and prevent the screen from fouling or blinding.

Media screens can also be arranged in parallel to better accommodate variable flows. Vertical screens with above-surface access ports can be used to enable better access for effluent sampling or occasional screen maintenance.

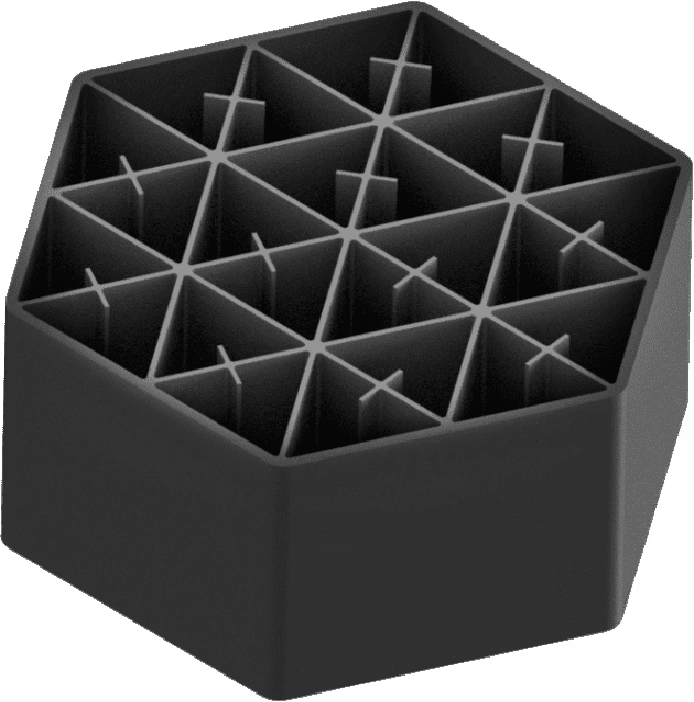

Fixed Grid Aeration

Thanks to our the integration with EDI, our aeration capabilities are the envy of the industry. Most BioPorts facilities are designed with EDI fixed grid aeration within our basins to optimize performance with minimal O&M.

In fact, based on that aeration expertise, Leeds, Alabama’s BioPorts MBBR is able to achieve optimized mixing and oxygen-transfer with ~25% of the energy typically required.

WHAT IT DELIVERS

BOD and Ammonia are no match for BioPorts

The BioPorts™ process is the best choice for roughing high influent BOD, polishing ammonia, or upgrading to IFAS. In place at dozens of installations across North America, BioPorts MBBRs deliver as promised and ensure that operators sleep well at night knowing they have the system in place to beat their BOD and nutrient limits.

FAQS

How much does a Bioports system cost?

How easily can a Biosports system be upgraded?

How often does Biosports media need to be replaced?

Does water need to be heated to achieve nitrification in a post-lagoon setting?

BioPorts is tremendously effective in many post-lagoon settings, so to identify which solution is best for you, reach out and let our NEI process engineers guide you.