Overview: The Challenge & Solution

The small footprint botanical like Organica solution solves a problem which arises with the massive urbanization we are experiencing today.

Conventional wastewater treatment plants are large and unpleasant facilities, typically built in the outskirts of cities. At the same time water scarcity becoming a pressing issue and it becomes clear that water needs to be recycled. Pumping the wastewater overlong distances to tradition treatment plants outside the cities and then pumping back the recycled water consumes lot of energy and is not a sustainable practice.

Our solution is based on two important pillars:

- A process which incorporates natural elements to form superior biofilm characteristics. As a result, the fixed films used in Organica facilities feature much more diversity and stability than traditional ones.

- Tight disciplinary integration fitting into the urban fabric requires more than a good wastewater treatment process. Much broader considerations including urban planning, architecture, smell, aesthetics, and psychology are required. Therefore, a much higher integration is ensured between process-, civil-, mechanical-, electrical engineering, architecture, landscaping, and botany.

ORGANICA FACILITIES INCORPORATE NATURAL PROCESSES AND ARCHITECTURAL PRINCIPLES

ADVANTAGES

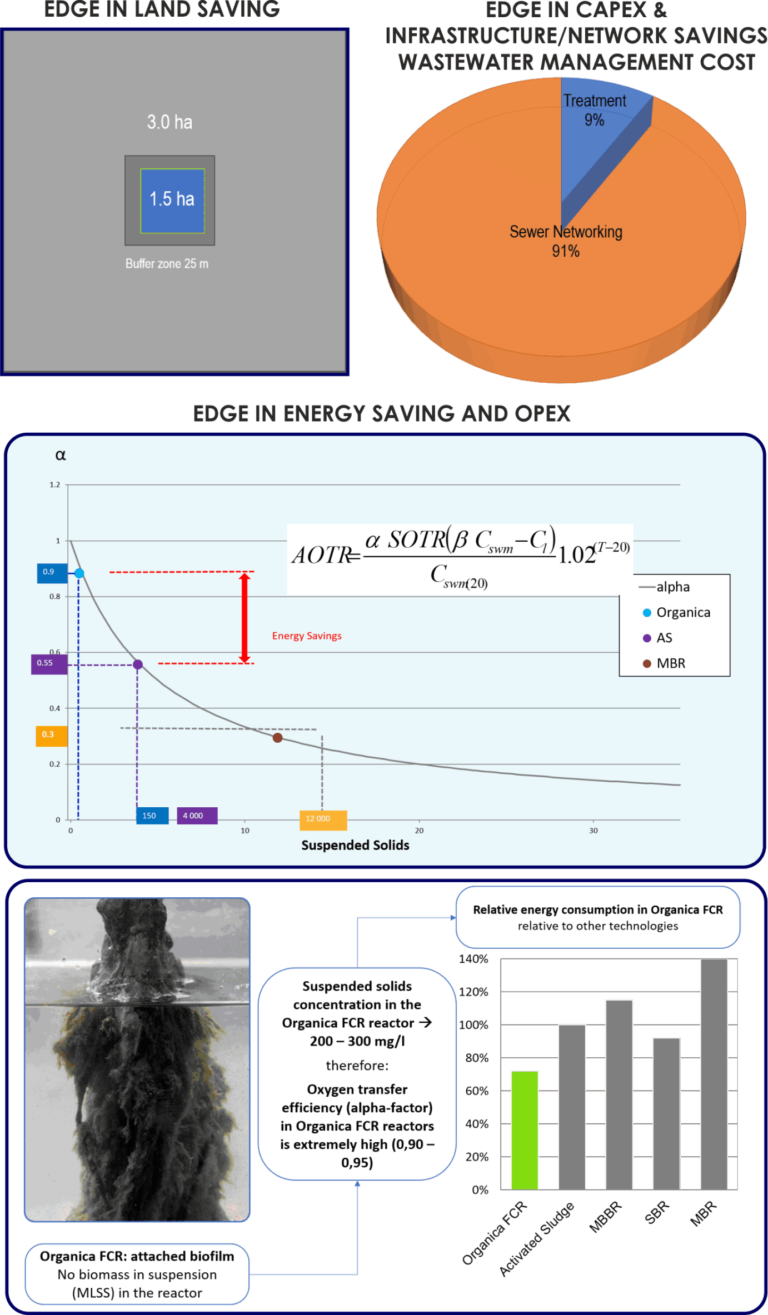

1. UP TO 60% SMALLER PHYSICAL FOOTPRINT

The efficient process produces larger biomass/m3 of reactor which leads to smaller overall reactor size. This combined with a creative architectural design results in 60% smaller physical footprints than an activated sludge design for the same application.

2. 30% OR GREATER REDUCTION IN OPERATING EXPENSE (OPEX)

The efficient process produces larger biomass/m3 of reactor which leads to smaller overall reactor size. This combined with a creative architectural design results in 60% smaller physical footprints than an activated sludge design for the same application.

3. UNIQUE LOOK & FEEL

With an attractive greenhouse or shading structure design and none of the typical wastewater treatment plant odors, the garden-like appearance of an Organica facility offers a positive “psychological” footprint. This means a pleasant impact on the surrounding environment which invariably means increased property values around the plant.

4. RESILIENT AND STABLE SYSTEM

The use of root structures as a biofilm carrier in the Organica FCR results in a substantial increase in the diversity of microorganisms present in the system. This enhanced diversity creates a highly stable system that can adapt to unexpected fluctuations in the loading of the influent wastewater.

ORGANICA FOOD CHAIN REACTOR (FCR)

KEY DETAILS

Technology: Food Chain Reactor (FCR) by Organica Water

ADVANTAGES

- Compact System

- Odorless

- Efficient

- Aesthetic

- 40% Savings on CAPEX & OPEX

APPLICATIONS

- Municipal Wastewater Treatmen

- Municipal Upgrade

- Real Estate Development

- Water Re-use applications

CASE STUDIES

- South Pest, Hungary WWTP

- MM2100, Indonesia WWTP

- Wusong, China WWTP

- Laguna, Philippines WWTP

- Gençay, France WWTP

LOCALIZED TREATMENT

– Many small facilities needed to

handle the same capacity

– Difficult & Costly to regulate &

operate so many facilities

– Each facility requires its own

sorrounding buffer zone

– Less tolerance for fluctuation in

influent quality

– Optimized solution between the

two extremes

– Connect local community to a

more sustainable future of

wastewater management

– Reduced network costs

– Maximizes development

opportunities

– Ability & accesses to potential

water reuse options

– Single or few facilities results in

economies of scale

– Usually located far from

wastewater source

– Extensive collection systems

needed

– Sufficient volume for reuse, limited

by distribution costs & available

demand

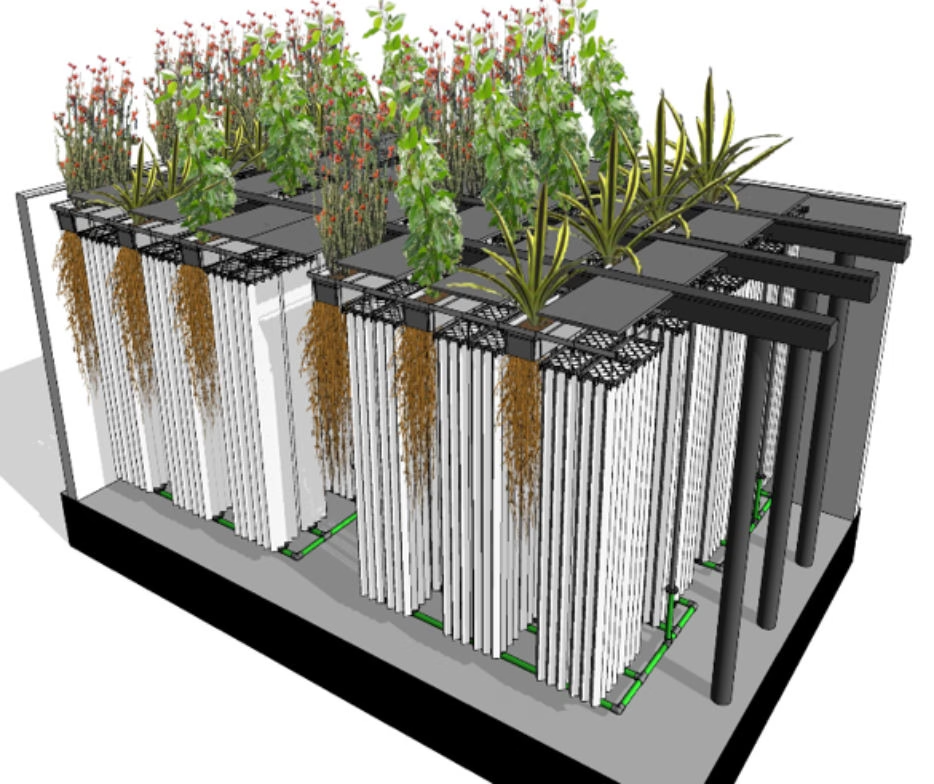

THE BIOMODULE

At the heart of an FCR Facility is the Biomodule. Designed to fit securely into the biological reactors, each Biomodule acts as the support structure for both the plants whose roots make up the primary biofilm carrier, and patented biofiber media designed to mimic the structure and function of the plant roots.

The root structures in turn provide an ideal habitat for a thriving ecosystem – both larger (2-4x greater active biomass per cubic meter of reactor volume) and more diverse (3-4x greater species diversity) than the biology found in typical conventional activated sludge-based systems.

This results in the development of a distinctive self-regulating ecosystem with operational flexibility and high resilience to unexpected influent fluctuations and shock-loading. In addition, because the Biomodules support this unique biofilm fixed on the root structures, the process utilizes much lower suspended solids content in the water (typically 90% less than conventional suspended growth systems). These lower suspended solids content improves oxygen transfer efficiency and results in significant energy savings.

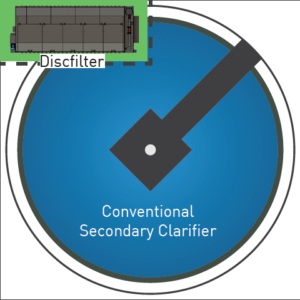

THE DISCFILTER

The Discfilter is a mechanical filtration device specially designed to remove total suspended solids (TSS) from wastewater streams following biological treatment in an FCR Facility. Each discfilter incorporates a simple, yet sophisticated, design that ensures continuous low-maintenance operation and stable, reuse-quality effluent; all with a drastically reduced footprint over conventional secondary clarification.

As an FCR Facility is a fixed-film system utilizing biofilm that is attached to root structures, the suspended solids content of the water in the treatment process is low (100 – 300 mg/l). This allows the use of Discfilters for phase separation directly after the biological treatment step.

REDUCES LAND REQUIREMENTS BY 90%

SEAMLESS INTERGRATION

REUSE-QUALITY WATER

As part of each FCR Facility, supplies and installs its process control software, custom programmed to operate the Facility efficiently and in an automated way. Utilizes a PC-PLC based process control system, integrating the acquisition, display, and storage of operational data, as well as the input and application of operational variables.

The control and management of the Facility relies on the data gathered from the sensors and probes installed in the Facility, specified by Organica at the design stage. The flow of wastewater is measured by electromagnetic meters and level indicators, while the optimization of energy consumption requires data from dissolved oxygen probes linked to variable speed drives controlling the blowers. Pump capacity is regulated via variable speed drives and electromagnetic or pneumatic controllers which regulate valves. All equipment is controlled by a PLC, which monitors their status through feedback channels and displays it on the application program.

The process control software provides an easy-to-use graphical interface for operator interaction and ensures secure operation of the whole treatment plant. The operational savings from this high level of automation are significant, as with this level of sophistication facilities require very few personnel for safe operation. In addition, the ability to establish secure online connections enables our engineers to provide clients with remote monitoring capability and various Digital Services. Using the online interface, engineers can remotely view, evaluate, and provide input to optimize Facility operation.

CONTROL AND INSTRUMENTATION

As part of our Digital Services, we do supply and install of highly automated control software, custom programmed to operate the wastewater treatment plant (WWTP) efficiently, while also allowing for seamless operation. We utilize a PC-PLC based process control system, integrating the acquisition, display, and storage of operational data, as well as the input and application of operational variables.

TECHNOLOGY ADVANTAGES

SMALLER PHYSICAL FOOTPRINTS

REDUCTION IN OPERATING EXPENSES (OPEX)

OPTIMIZED SLUDGE PRODUCTION

ARCHITECTURAL DESIGN

SHORTER CONSTRUCTION TIME

RESILENT AND STABLE SYSTEM

TECHNOLOGY APPLICATIONS

MUNICIPAL WASTEWATER TREATMENT

ORGANICA PLANT IN A SUBURB

VANCOUVER, CANADA

Wastewater treatment can occur in dense city neighborhoods, minimizing the number one cost in wastewater infrastructure: the piping network.

Treatment close to the waste source creates opportunities for localized water reuse, thereby decreasing pressure on drinking water infrastructure.

Urban landscape is actually positively impacted by the presence of ‘Urban Water Gardens’.

MUNICIPAL UPGRADE

ORGANICA PLANT IN A SUBURB

VANCOUVER, CANADA

Upgrades of existing wastewater treatment facilities can increase capacity, improve effluent quality, and decrease operational costs.

In cases where the city has developed around the old wastewater treatment facility, the technical improvements from upgrades are coupled with a transformation from industrial to natural, enhancing neighborhoods and improving the surroundings.

Urban landscape is actually positively impacted by the presence of ‘Urban Water Gardens’.

REAL ESTATE DEVELOPMENT

ORGANICA WATER RESOURCE FACILITY IN THE MIDDLE OF A REAL ESTATE DEVELOPMENT

CHINA

With a small building envelope, beautiful garden aesthetics, and no odor, land value is maintained and, in many cases, even improved.

Simple operation and lower energy consumption along with on-site water reuse opportunities will bring savings over time and make any development much more sustainable.

Urban landscape is actually positively impacted by the presence of ‘Urban Water Gardens’.

INDUSTRIAL PARKS

THE ORGANICA FACILITY IN THE MIDDLE OF A TRAFFIC CIRCLE IS TREATING AND RECYCLING THE WATER FOR IRRIGATION

HAINAN ISLAND, CHINA

Treated effluent is of a high quality and local reuse needs can easily be met without additional treatment.

Social acceptance of wastewater reuse is facilitated by the incorporation of nature – a thriving healthy garden – in the facility.

Globally Treating 1,314MLD (15,200 L/S)

5.2M PEOPLE SERVED

WORLDWIDE

RUNNING SYSTEMS

GLOBAL AWARDS

Judges’ and People’s Choice on the "Decentralized Water Reuse Solutions" Tech Tank at Sydney Water Innovation Festival 2022

Cleantech 100 list and Cleantech Hall of Fame (2020)

Paulson Prize for Sustainable Cities - (Wusong- 2018)

Corporate Growth Award (2018) by Association for Corporate Growth

Water Reuse Gardens - Best Presentation/Paper and Best Innovation (2018) by ALADYR Conference Technical Committee

2018 Corporate LiveWire’s Innovation and Excellence Awards

Environment and Climate change Award South Africa The Institute of Municipal Engineering of Southern Africa (IMESA)

Paulson Prize for Sustainable Cities - (Wusong- 2018)

Recommended Technology (2017) Secretary General of the China Water Association, Qingdao Water Conference

Best Performer in Global Expansion (2017) Idinvest International

Frost & Sullivan Best Practices - Global Biological Wastewater (2017)

GWI Industrial Water Project of Year (2016),

MM2100 WWTP

Cleantech Connect Most Innovative (2016)

by GP Bullhound

Lux Research Top Ten Global Innovative Company (2015) Profiled 1200 companies across 20 sectors/selected 10 most innovative

Global CleanTech “Company of the Year” - Europe & Israel (2013) by CleanTech Group

Global CleanTech TOP 100 (2013, 2014, 2015, 2016, 2017, and 2018) by CleanTech Group (only water company 6 consecutive years)

GWI Wastewater Project of the Year (2013)

South Pest WWTP

Water and Energy Exchange (WEX) Innovation Award (2013) recognizing significant achievement in field of Water and Wastewater

The "Environment Award" (2004 and 2008) by the Hungarian Association of Environmental Manufacturers and Service Providers

Company of the Year (2004) by Hungarian VC/PE Association

WHAT DO WE DO TO MAKE IT HAPPEN?

1. Engineering support

this ensures the integration of disciplines, and forms the basis of our process guarantee.

When cooperating with a Partner, both on proposal and project implementation phases, Organica devotes a full team of dedicated engineers that are able to adapt to Partner´s specific support needs to create a highly-detailed engineering package. This can cover all the technical aspects/disciplines of engineering for the complete wastewater treatment plant: process design, detailed mechanical engineering, control and instrumentation, and civil & architectural design.

In addition to the above, thanks to Organica’s highly automated process modelling capabilities, design/engineering software and specialized engineers, the engineering documents are generated in a very short timeframe, ensuring both optimized design and on-time delivery.

2. Everything that is in the reactors (these components to ensure that the process works as intended)

Biomodules – engineered media blocks within the reactors, enabling large quantities of biomass to grow and remain active.

Plant racks – these supports natural (plant roots) biological media in the form of a beautiful garden bed on the reactor surface.

Aeration panels – specially designed to snugly fit beneath each biomodule, enhancing hydraulic mixing and oxygen transfer efficiencies.

Discfilters – Specially designed as a small footprint phase-separation step directly after the biological reactors, which ensure compliance with strict effluent TSS requirements.

Control & Instrumentation – integrated sensors and software package to ensure efficient operation.

Commissioning Support / Supervision – to ensure process performance and secure process guarantee delivery.

- PATENTED PROCESS

-

FCR Process Overview

- The Challenge & The Solution

- Organica Facilities Incorporate Natural Processes And Architectural Principles

- Organica Food Chain Reactor (FCR)

- Localized Treatment

- The Biomodule

- The Discfilter

- Control And Instrumentation

- Technology Advantages

- Technology Applications

- Global Awards

- What Do We Do To Make It Happen?

- Process Background

- Integration